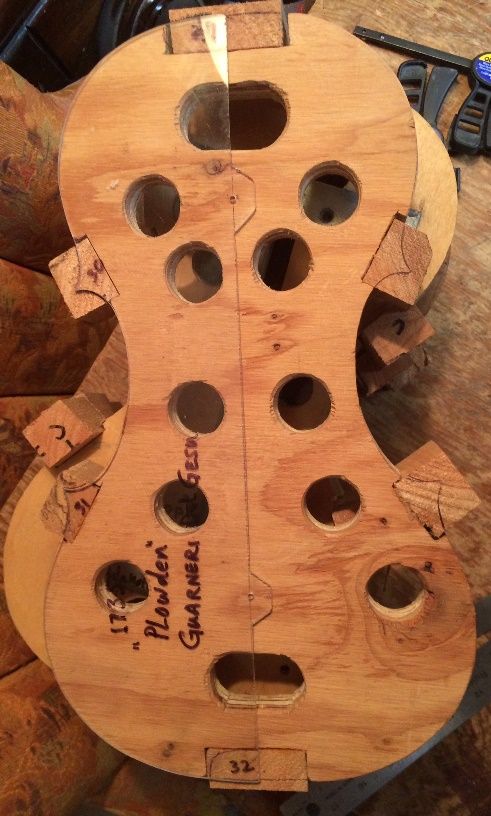

Build Progress for a couple of new “5-string Bluegrass fiddles:”

Last time:

Last post showed the garlands complete, and ready to be leveled:

I began the leveling process using a file and a finger plane, until the fragile rib-edges were level with the linings.

Then I completed the leveling by rubbing the garland on a sanding board.

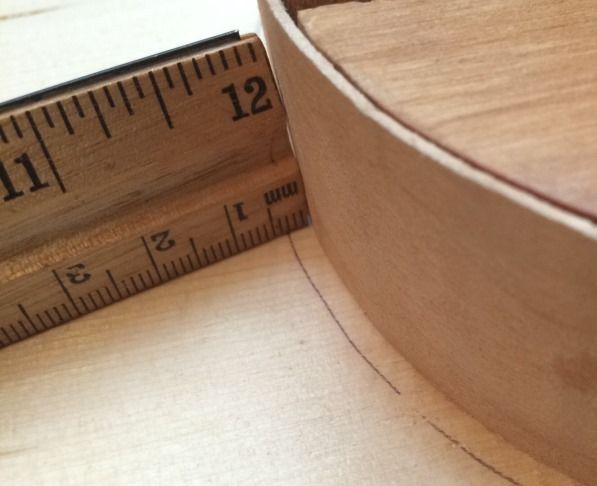

Tracing the plates

Once the garlands were flat, I could use them to trace the outline of the plates: I used a small washer as a tracing tool– as a spacer, to give me the overhang distance I want (3mm.)

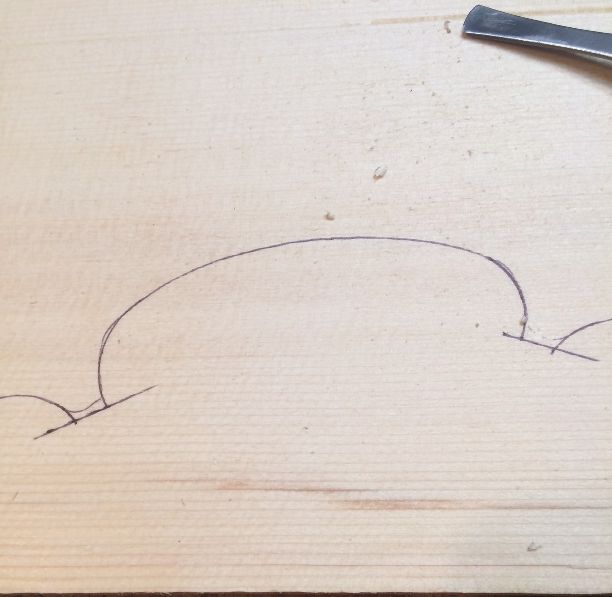

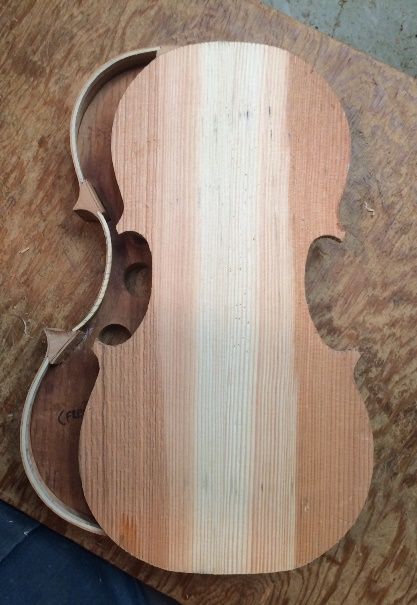

Correcting the corners and cutting out the plates

I really don’t want the “round corners ” produced by the washer, but they do give me a starting point from which to correct the corners before cutting out the plates:

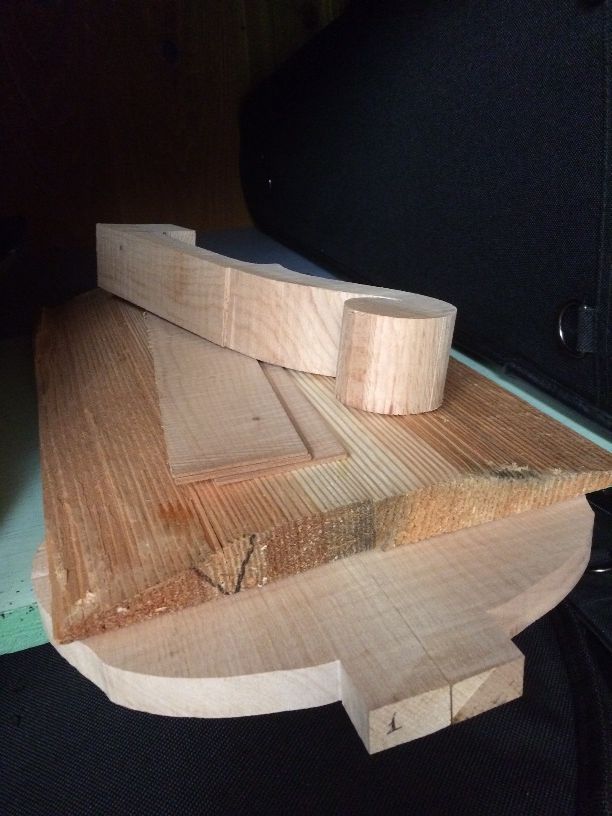

Arching the plates:

Arching the plates is a critical step, because the arching pretty much controls the tone quality. In fact, it may be the single most inportant factor in achieving good tone. I begin by scribing the edge-thickness of the plates and then I begin removing waste wood to complete the rough arching:

I use arching templates to establish the shape of the arching, and then fair-in the parts in between the templates. (The templates for the back plate are slightly different, but all of these things matter: I have to use them correctly. And, although I can get the arching “close” without the templates, quite honestly, “close” isn’t good enough.)

.jpg)

Laying out F-holes, and incising them.

After the arching shape is very close to correct, I use templates to lay out the f-hole shapes and locations, and then use a knife to incise the lines deeply, so that I can’t accidentally remove the lines through further shaping.

Then I refine the arching, using gouges, planes and scrapers, until the shape is exactly what I want.

Purfling:

The word “purfling” evidently comes from the old Italian “por filo” meaning edging. It supposedly helps strengthen the edge, and it certainly helps “define” the edge, and…it looks nice. Though there are examples of old intruments without purfling, all of the better “Old Master” makers used it, and I will never make an instrument without it. (Besides…I like it.)

I position the purfling beginning at 4mm inside the outer rim of the plates, and mark the location of both sides of the slot, using a purfling marker (sometimes called a purfling cutter.) The marker won’t work for the corners, so I have to lay them out using a pencil.

Then I use a knife to incise those lines deeply enough to receive the actual purfling strips.

Finally, when the slots are complete, I can begin inserting the actual purfling strips. The strips come as 32″ long three-ply veneers, and are very brittle. I have to use the bending iron to prepare them for insertion into the slots.

.JPG)

Gluing the Purfling:

After the purfling strips are correctly fitted, dry, I carefully lift them out, one by one, and slip hot hide glue into the slot beneath each strip, then quickly force the strip back into the slot, ramming it home with a special tool.

When all is complete, I allow the purfling to dry, before moving on to cutting the channel, performing the final edgework, and fairing the channels into the arching…but those are stories for another day. 🙂

Thanks for looking.